Çok amaçlı kuşbaşı ve sebze doğrama makinası ile size bugüne dek uzun zaman harcayarak el ile yaptığınız doğrama işlemini çok daha pratik ve çok daha güzel bir şekilde yapabileceğiniz bir sistem sunuyor. Devinoks güvencesi ile üretilen çok amaçlı doğrama makinesi ile et, ciğer ya da her türlü sebzenizi istediğiniz şekillerde doğrayabiliyorsunuz. Hem daha az vakit harcıyorsunuz, hem de en güzel sonuca en pratik şekilde ulaşıyorsunuz.

Çok amaçlı doğrama makinası ile doğramak istediğiniz et, tavuk , ciğer, biftek, sucuk, salam, kaşar peyniri, patates, soğan, patlıcan, salatalık, turşu, havu, turp, ve benzeri ürünleri küp, dilim ve cips şeklinde doğrayabilirsiniz. Uygulama alanları başta: Et entegre tesisleri, marketler, kasaplar, oteller ve yemek fabrikaları iş veriminizi arttırmak ya da müşterilerinize iyi olanı sunmak... Amacınız hangisi olursa olsun Devinoks Endüstriyel Gıda Makinaları ile en iyi sonuca ulaşacaksınız.

Kuşbaşı, Tavuk, Ciğer ve Et Doğrama Makineleri | Endüstriyel Kesim Çözümleri

Kuşbaşı, Tavuk, Ciğer ve Et Doğrama Makinelerinde Profesyonel Çözümler

Endüstriyel mutfakların en büyük ihtiyaçlarından biri, hızlı ve hijyenik doğrama işlemlerini gerçekleştirebilen profesyonel makineler kullanmaktır. Bu noktada kuşbaşı doğrama makinası, et işleme süreçlerinde zamandan tasarruf sağlarken, ürün kalitesini de artırmaktadır. Kesim işlemlerinde standart boyutların korunması, özellikle restoran, catering ve et işleme tesisleri için oldukça kritiktir.

Günümüzde sadece kırmızı et değil, tavuk ve sakatat gibi ürünlerin doğranmasında da otomatik makineler tercih edilmektedir. Özellikle tavuk doğrama makinası, hem bütün tavukların hem de tavuk parçalarının istenilen boyutta kesilmesini mümkün kılar. Bu makineler, el ile yapılan kesimlere kıyasla daha güvenli ve hijyeniktir.

Ciğer doğrama makinası ise yumuşak ve kaygan yapıya sahip olan sakatat ürünlerinin düzgün bir şekilde kesilmesini sağlar. El ile doğrama sırasında karşılaşılan şekil bozuklukları ve ürün kayıpları bu makineler sayesinde en aza indirgenir. Ayrıca üretim kapasitesini artırmak isteyen işletmeler için bu makineler kaçınılmaz bir yatırım olarak öne çıkar.

Et doğrama makinası çeşitleri, her işletmenin ihtiyacına göre farklı boyut, kapasite ve kesme özelliklerine sahiptir. Paslanmaz çelik gövde yapıları, hijyen standartlarına uyumlu tasarımları ve kolay temizlenebilir parçaları sayesinde gıda güvenliği açısından ideal bir kullanım sunar. Özellikle etin taze işlenmesi ve besin değerinin korunması açısından büyük avantaj sağlar.

Bu makinelerin kullanımında dikkat edilmesi gereken en önemli unsurlar arasında bakım ve temizlik süreçleri yer alır. Her kullanım sonrası makinelerin detaylı bir şekilde temizlenmesi, hem uzun ömürlü kullanım sağlar hem de bakteri oluşumunun önüne geçer. Ayrıca, CE belgeli ve gıda ile temasına uygun malzemelerle üretilmiş modeller tercih edilmelidir.

Günümüzde birçok endüstriyel mutfak, insan gücünü minimize ederek üretkenliği artırmak adına doğrama makinelerine yönelmektedir. Özellikle yoğun üretim yapan işletmelerde kuşbaşı doğrama makinası, tavuk doğrama makinası, ciğer doğrama makinası ve et doğrama makinası gibi ekipmanlar, hem zaman hem de maliyet açısından ciddi avantajlar sunar.

Sonuç olarak, gıda sektöründe profesyonel ekipmanlar ile çalışmak, hem kaliteyi hem de müşteri memnuniyetini artırır. Doğru doğrama makinası seçimi, işletmenizin ihtiyaçlarına göre belirlendiğinde üretimde büyük bir fark yaratır. Devinoks gibi güvenilir markaların sunduğu makinelerle siz de mutfağınızda fark yaratabilirsiniz.

|

Kapasite

|

Kg/saat

|

72 / 180

|

|

İtici Hareket

|

mm

|

1-35

|

|

Hazne Ölçüsü

|

mm

|

75 x 75 x 305

|

|

Elektirik Gücü

|

kW

|

0.55

|

|

Makine Ölçüleri

|

mm

|

590 x 700 x 680

|

|

Ağırlık

|

Kg

|

120

|

· Patentli döner daire bıçak teknolojisi dünyada ilk devinoks makine tarafından kullanılmıştır,

· Makine dış gövde bildirimleri ve bağlantı ekipmanları 304 paslanmazdır,

· 2 yıl garantilidir,

· Kesme boy ayar butonu,

· Su geçirmez Elektirik sistemi,

· Ön kapak ve üst kapak güvenlik sensörü,

· Et doğrama sıcaklığı 0, -2 C derecedir,

· Üst kapak sensörü sayesinde hazne doldurulup kapak kapandığında otomatik çalışma özelliği

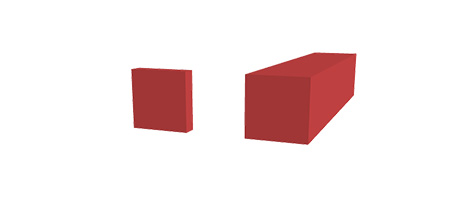

Kuşbaşı doğrama Şekilleri

Küp Küp Doğrama (Paysanne) (dice)

Bu doğrama şekilinde ölçülerimiz bıçak değiştirmek sureti ile kaba ayar yapılır daha sonra elektronik değişken hız ayar metresi ile 1 mm ile 35 mm arasında ince ayar yapılarak aşağıdaki ölçülerde kesim yapılabilir;

|

8 x 8 x 1 mm ile 35 mm arasında kesim yapılabilir

|

|

|

18 x 18 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 28 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

39 x 39 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

39 x 59 x 1mm ile 35 mm arasında kesim yapılabilir

|

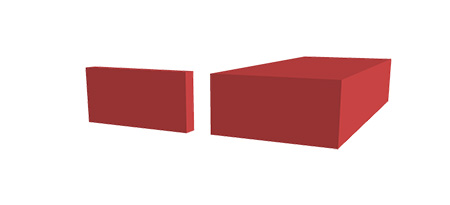

Parmak Doğrama (Batonnet)

|

8 x 18 x 1 mm ile 35 mm arasında kesim yapılabilir

|

|

|

8 x 28 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

8 x 37 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

8 x 59 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

8 x 120 x 1mm ile 35 mm arasında kesim yapılabilir

|

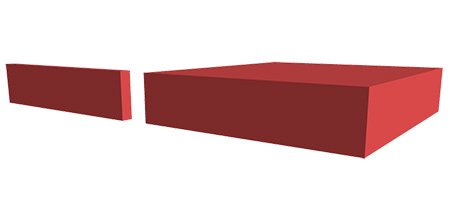

Parmak Doğrama Büyük (Pont neuf)

|

18 x 18 x 1 mm ile 35 mm arasında kesim yapılabilir

|

|

|

18 x 28 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

18 x 37 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

18 x 59 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

18 x 120 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 18 x 1 mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 28 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 37 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 59 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

28 x 120 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

37 x 59 x 1 mm ile 35 mm arasında kesim yapılabilir

|

|

37 x 120 x 1mm ile 35 mm arasında kesim yapılabilir

|

Yuvarlak Doğrama (Vichy)

1mm ile 35 mm arasında doğrama

|

39 x 39 x 1 mm ile 35 mm arasında kesim yapılabilir

|

.jpg)

|

|

39 x 59 x 1mm ile 35 mm arasında kesim yapılabilir

|

|

39 x 120 x 1mm ile 35 mm arasında kesim yapılabilir

|